Rust Converter & Encapsulator: How to Stop Rust

Learn why rust converter and encapsulator products fail when you skip surface prep. Expert tips for stopping rust permanently on metal surfaces.

Homevisory offers a home maintenance app, but our editorial content is independent. Product recommendations are based on merit, not business relationships.

Most People Get This Backwards

I see the same mistake constantly. Someone notices rust on their truck frame or their patio furniture or their basement pipes and they go buy a can of rust converter paint, slap it on, and then act surprised when the rust comes back in six months.

The product wasnt the problem. The prep was the problem. Its always the prep.

A rust encapsulator or converter is only as good as what you do before you open the can. I learned this the hard way about twenty five years ago and I still think about it more than I probably should.

What Rust Converter Actually Does

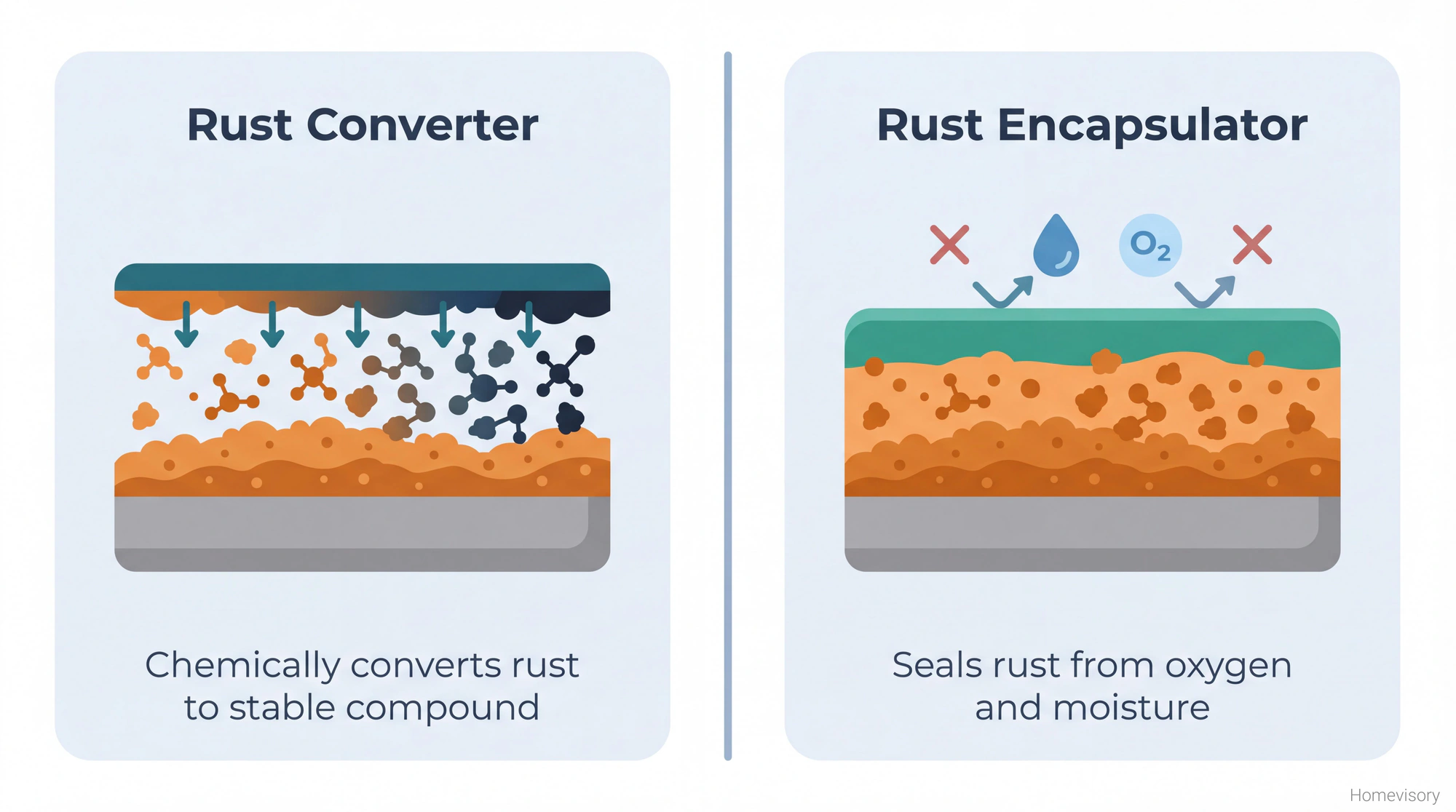

Lets get the basics out of the way. Rust converter is a chemical treatment, usually containing tannic acid and some kind of organic polymer, that reacts with iron oxide, which is rust, and converts it into a stable compound called iron tannate. This new compound is black or dark gray and it creates a surface that paint can actually bond to.

A rust encapsulator works differently. It doesnt convert the rust chemically. It seals over it, creates a barrier between the rust and oxygen and moisture. No oxygen means no continued oxidation. The rust stops spreading.

Some products do both. They convert what they can and encapsulate the rest.

Heres what matters: neither one is magic. Neither one works on loose flaky rust. Neither one penetrates through thick scale. If you skip the prep, you’re just putting expensive paint over garbage and hoping for the best.

The Real Problem Nobody Wants to Hear

The best rust converter in the world cannot fix lazy prep work.

I say this as someone who has made every shortcut mistake you can make. In 2011 I tiled directly over old tile in my own bathroom because I didnt want to spend a weekend demoing. Eleven months later the tiles were popping off and my subfloor was rotting. Raquel made me sleep on the couch because I smelled like mold for three days while I fixed it.

Rust is the same principle. You cannot seal over active decay and expect it to hold. The rust underneath keeps working. It pushes. It flakes. It undermines whatever youve put on top. Then the whole thing fails and youre back where you started except now youve wasted time and money.

My dad worked at a factory in Atlanta for thirty years and he used to say rust doesn’t sleep. He meant it literally. Oxidation is a chemical reaction thats happening every second that metal is exposed to moisture and air. You can slow it down. You can stop it. But you have to actually stop it, not just cover it and pretend.

Surface Prep Is Ninety Percent of the Job

This is the part where I’m going to go on longer than necessary because I’ve seen too many people skip it.

You need to remove all loose rust. All of it. Every flake, every scale, every bit thats not firmly attached to the base metal. Wire brush, wire wheel on a drill, angle grinder with a flap disc, whatever you have access to. The goal is to get down to either solid metal or rust thats so tight to the surface that its essentially part of the metal now. That tight rust, the stuff that wont come off with aggressive wire brushing, thats what the rust converter is designed to handle. Not the chunky stuff. Not the stuff thats already lifting. If youre applying rust converter spray over rust that crumbles when you poke it, youre wasting your time and I genuinely dont know what to tell you except start over and do it right. The number of times Ive seen people spray over active rust piles and then post on forums asking why their rust encapsulator failed, it drives me crazy because the answer is always the same. You didnt prep.

After mechanical removal, degrease the surface. Rust converter needs to contact bare rust and bare metal. Grease and oil create a barrier that prevents the chemical reaction.

Some people use naval jelly or phosphoric acid prep before applying rust converter. If youve got pitting or tight rust in crevices that you cant reach with a wire brush, this helps. Apply it, let it sit, neutralize it, let it dry completely.

Dry is important. Moisture trapped under a rust encapsulator will cause problems. Most products say to apply to a dry surface but they dont emphasize how dry. Not damp. Not recently rained on. Dry.

The Ben Disaster Trailer

Back in 1999 I went into business with a guy named Ben. We called it MB Home Renovations. It ended badly, he disappeared with seventy two thousand dollars in materials and client deposits, but thats a different story.

What I remember now, twenty six years later, is a trailer we bought together for hauling demo debris. Used trailer, rusted underneath, but the price was right and we figured we’d fix it.

Ben wanted to spray it down with rust converter and call it done. I said we needed to grind it first. He said that was a waste of time. We compromised by doing half and half. His side got sprayed over rust scale. My side got ground down and then sprayed.

His side was flaking again before he left with my money. My side held.

I think about that trailer sometimes. Not because of the rust lesson, I already knew the lesson. My dad had been showing me how to treat tools since I was probably ten or eleven. He had this shovel, green handle, and one spring he pulled it out of the shed and the blade had surface rust all over it from winter moisture. He wire brushed it in the driveway, treated it with something, I dont remember what, and then painted it. He let me help. I dont know why I still remember that.

Anyway. The trailer. Point is, even then, I knew prep mattered.

Rust Converter Paint vs Spray vs Brush On

Three formats, basically. Rust converter spray in aerosol cans. Brush on rust converter paint. And spray gun products for larger jobs.

The aerosol rust converter spray is convenient for small jobs. Mufflers, small tools, brackets, hinges. Coverage isnt as heavy as brush on but its faster and gets into tight spots.

Brush on gives you more control over thickness. Two coats is standard. Let the first coat cure before the second.

For the best rust converter results, application matters more than brand. Thin even coats. Full coverage. Proper cure time between coats. Most products need 24 to 48 hours to fully cure before you can topcoat with regular paint.

Brand debates are endless. Permatex, POR-15, Rust-Oleum Rust Reformer, Corroseal, Eastwood. They all work. Whatever works. Just use it correctly. The failure rate comes from application errors not product chemistry.

Rust Encapsulator Specifics

A dedicated rust encapsulator like POR-15 or Eastwood Rust Encapsulator is designed to go over prepped rust and seal it permanently. These are typically harder and more durable than standard rust converter paint.

Application rules:

Do not apply thick coats. Thick coats trap solvents and cause adhesion failure.

Most rust encapsulators require a topcoat if exposed to UV. They chalk and degrade in direct sunlight. So if youre doing something thats going to see sun, plan on priming and painting over the encapsulator.

Read the recoat window. Some products have a window where you must recoat or topcoat before a certain time, or you have to scuff the surface for adhesion. Miss that window and youre sanding.

Temperature matters. Too cold and it wont cure properly. Too hot and it skins over before solvents escape.

What About Laser Rust Remover

People ask about this. I’m not getting into it.

Laser rust removal is real, it works, it looks incredible in videos. Its also industrial equipment that costs thousands of dollars. Unless youre running a restoration shop or military contractor, you dont need to know about laser rust removers. Wire brush and rust converter. Thats the homeowner path.

Moving on.

When to Use What

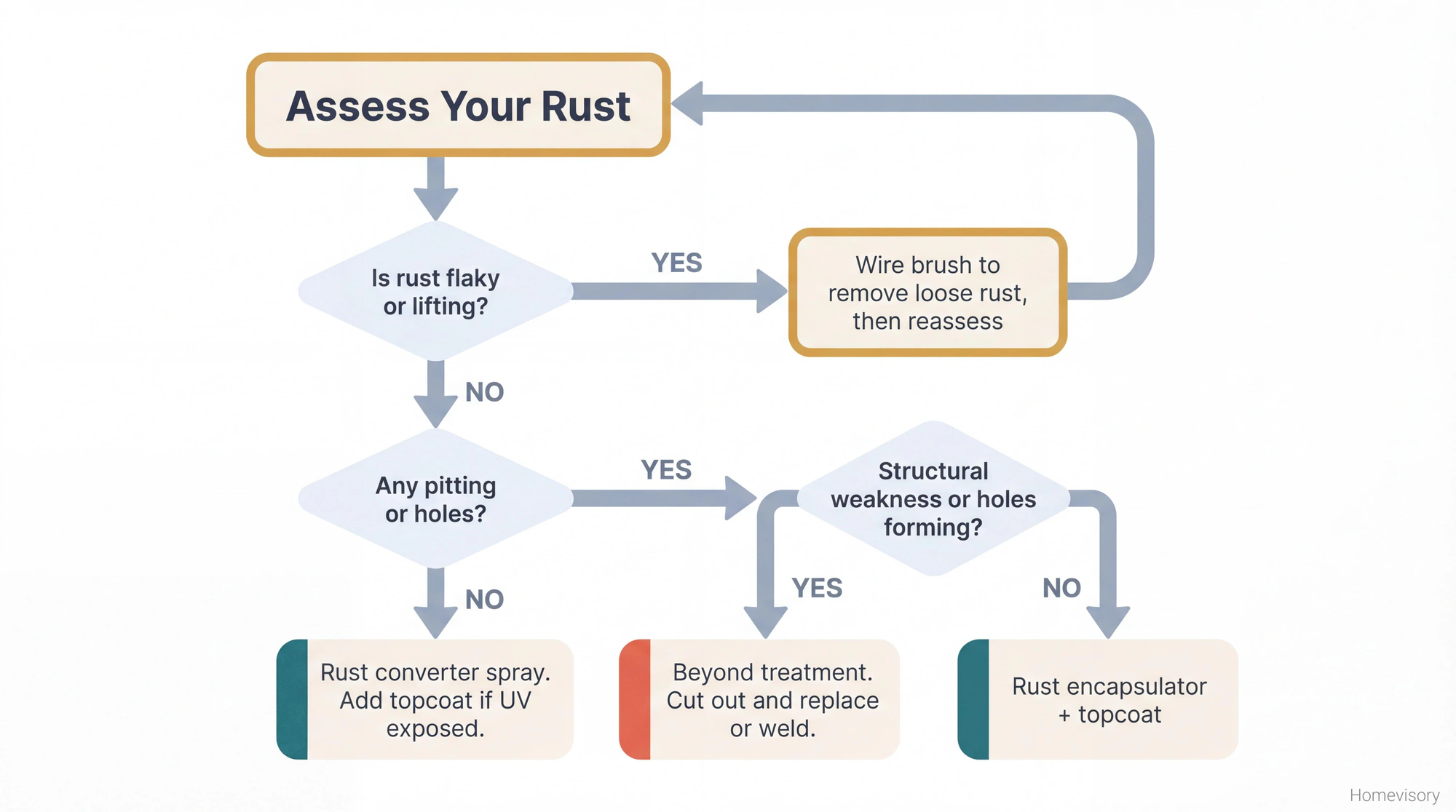

Surface rust, light orange discoloration, hasnt pitted the metal yet: wire brush, degrease, rust converter spray, topcoat if needed.

Moderate rust, some pitting, but structurally sound: mechanical removal of loose scale, chemical prep if needed, rust encapsulator, topcoat.

Heavy rust, structural compromise, holes forming: youre past the point of rust converter paint. You need to cut out the damaged section and weld in new metal, or replace the part entirely. No product fixes structural rust.

The Marketing Problem

Every rust product makes big claims. “Stops rust permanently.” “Never comes back.” “One coat protection.”

I dont trust any of it. Marketing is marketing.

What I trust is physics. If you remove loose rust, convert or encapsulate whats left, seal it from moisture and oxygen, and topcoat for UV protection, the rust stops. Not because of marketing claims. Because you removed the conditions that cause oxidation.

If you skip any step, the rust comes back. The product didnt fail. You failed the product.

My mom Shirley used to say, about cleaning, that how you do the small things is how you do everything. I think about that with prep work. The wire brushing that nobody sees. The degreasing. The waiting for it to dry completely. The thin coat instead of the thick one. Nobody sees any of it. The paint covers it all.

But the rust knows. The chemistry knows.

What Homevisory Does With This

We built Homevisory to track the maintenance stuff that falls through the cracks. Rust inspection on outdoor metal, fence hardware, patio furniture, tool storage, basement pipes, is the kind of thing you do once a year and then forget about until somethings already failing.

The Homevisory home task manager sends reminders for seasonal maintenance. Spring rust check on outdoor furniture. Fall inspection of fence hardware before winter moisture. You can sign up free and add custom tasks for whatever your house needs.

Thats what we do here at Homevisory. We help you remember the small stuff before it becomes expensive stuff.

Because rust doesn’t sleep. But you can at least set a reminder.

Mark Carter

Content Writer

Mark Carter is a home maintenance expert with over 20 years of experience helping homeowners maintain and improve their properties. He writes practical, actionable guides for Homevisory to help you tackle common home maintenance challenges.

View all articles by Mark CarterRelated Articles

Ceiling Fan Direction: Summer vs Winter Settings Guide

Learn how to set your ceiling fan direction for summer and winter. Counterclockwise for cooling, clockwise for heating. Simple switch saves energy year-round.

How to Remove Oil Stains from Driveway & Concrete

Learn how to clean oil stains from driveway concrete using proven methods. From fresh spills to set-in stains, get step-by-step solutions that actually work.

How to Balance a Ceiling Fan: Stop Wobbling & Noise

Learn how to balance a ceiling fan in 30 minutes with simple DIY steps. Fix wobbling fans safely without an electrician - just a ladder and $4 kit.